A group of Hort2thefuture partners visited Hunton, a leading wood-fibre-based material producer in Norway. While the use of wood fibre in the paper industry is declining, it is increasingly finding its way into circular products such as insulation materials and horticultural substrates. In fact, Hunton’s annual production capacity of 1,000,000 m³ of wood fibre is largely exported to potting-soil producers outside Norway, including in Scandinavia, Belgium, Australia, the Middle East, and Sri Lanka.

From wood chip to growing media: A sustainable process

The site at Gjøvik, operating since 1932, is one of Hunton’s four plants and specialises in producing insulation materials and growing media from fresh, locally sourced wood chips. Its insulation products consist mainly of Windproof™ and Underroof™ boards for the building industry, while growing media represent a newer and rapidly expanding market. All Hunton products are made using 100% local PEFC-certified spruce wood (a 60-year crop), sourced daily within a 50 km radius of the Gjøvik facility. The freshness of the material and the use of a single wood species ensure a high level of homogeneity and uniformity.

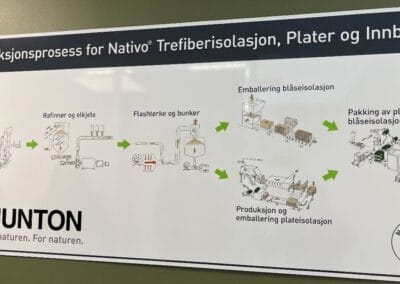

Upon arrival at the plant, the fresh wood chips undergo defibration, a process in which the chips are washed and heated with steam to break down the lignin, followed by pulping with press discs. In the next stage, the fibres are dried in what Hunton refers to as “the largest hairdryer in the world”: a flash dryer powered by green electricity and operating at 180 °C, capable of producing up to four tonnes of dry, fluffy wood fibres per hour. Drying the fibres allows for greater compression and ensures long-term storage stability.

The processed fibres are then ready for two main product lines: hand-pressed mats or loose fibres. These are used for thermal and acoustic insulation in construction, as well as for horticultural substrates. The compressed fibres can be mixed with biodegradable binders and are available in three main formats (slabs, plugs, and cubes) depending on the required thickness.

Collaboration with NIBIO – Hort2thefuture project partner

Since 2019, Hort2theFuture project partner NIBIO has been working closely with Hunton to develop wood-fibre-based growing media, leading to the launch of Fibergrow® in 2022.

According to NIBIO, aligning and pressing the fibres with bio-binders ensures good capillarity and irrigation performance, supporting root development comparable to that achieved with peat-based substrates. Wood-fibre growing media are already widely used for crops such as strawberries, berries, tomatoes, and cucumbers

NIBIO and Hunton are also researching ways to impregnate wood-fibre substrates with ammonium sulphate (instead of urea), which provides additional nitrogen while helping to lower and stabilise the substrate’s pH.

What sets Hunton Gjøvik apart is its commitment to industrial symbiosis and maintaining a low carbon footprint, transforming hydropower and biomass into high-quality bio-based products. The company places strong emphasis on research and development and collaborates closely with both the building sector and the growing-media industry.

Importantly, Fibergrow® can be reused as a growing medium, composted, or recovered for energy, supporting circular economy principles.